Yamabe Taishi

Taiko Performer, composer, producer

He has created Japanese pop music including Taiko sound, and been pursuing Taiko’s new aspects and probability, then remaining wonderful Japanese songs along with creating Japanese performing state. He is the one of the best Japanese Taiko performers and creators that Japanese should be proud of.

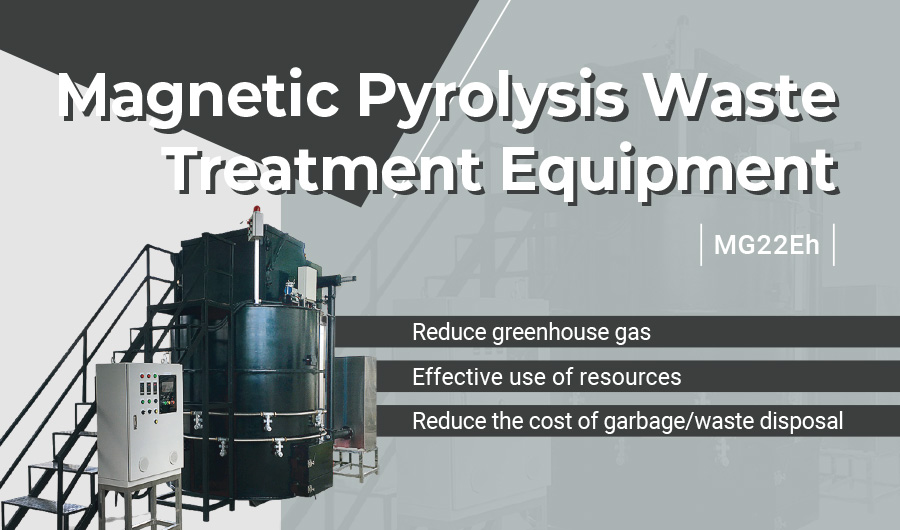

Magnetic pyrolysis waste treatment equipment

"MG22Eh"

This equipment makes the secondary use of wastes and reducing greenhouse gases both possible.

We contribute to corporate ESG management through innovative technology.

Product features

- Organic matter is decomposed using only magnetism as heat source and inside the equipment , burning with flame is not necessary, and the powder after process can be used for secondary purposes.

- It is possible to process organic matter from approximately 800kg to 1t per day.

- It is fully automatic and can operate at full capacity of twenty-four seven.

- Safety is assured through automatic control.

- No approval and/or qualification is required for use. It can be used with just a simple button operation.

- Since the inside of the furnace oxygen concentration level is kept under the standard, no carbon dioxide is emitted. In addition, the amount of dioxins also clears the environmental standards.

Product usage scenarios

1. Utilization as waste treatment equipment

By reducing the volume of organic waste to approximately from 0.003% to 0.004%, processing costs can be significantly reduced.

The inside of the furnace oxygen concentration level is kept under the standard, and the mechanism need not combustion by flames. That’s why it does not emit carbon dioxide. And it only uses a smaller amount of electricity and kerosene than originally used, as its operating power is waste treatment. By significantly reducing energy consumption, it greatly contributes to measures to reduce greenhouse gas emissions.

In addition, the remained ash after treatment process can be used as reinforcing agent of concrete or as soil conditioner, so no resources are wasted.

It is a truly a revolutionizing and a cutting age equipment.

2. Utilizing as a generator of valuable resources

Usage example

Generating industrial silicon from solar panels

By using MG22Eh to decomposing solar panels that scheduled for disposal, industrial silicon its purity is approximately 75% can be produced. It will contribute to the effective use of waste panels, which is our subject to treat with globally.

![]()

Disassemble waste tires and recycle the wire parts

By pyrolyzing waste tires, only the contained wire parts are extracted.

Since the inside of the MG22Eh furnace is kept under the standard oxygen concentration level, unlike heat treatment process, wire are not oxidized during process, making it useful as an effective recycling resource.

Generate silica from rice husk

Silica (amorphous/water-soluble) is produced from rice husks that are already discarded.

For example, in Japan, approximately 20% of the rice husks produced are discarded without being used effectively.

MG22Eh contributes to the effective use of resources.

Event

Feature

SNS

We send the latest information on our Instagram account.